20

Nov

Maximizing Flow Efficiency With HDPE Pipe Design

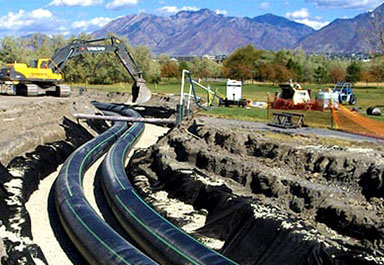

High-Density Polyethylene (HDPE) pipes are increasingly becoming a preferred material for piping systems due to their versatility, durability, and efficiency. This article delves into how HDPE pipe design can be optimized to maximize flow efficiency, a critical factor in various applications such as water supply, sewage, and industrial fluid transport.

Understanding HDPE Pipes

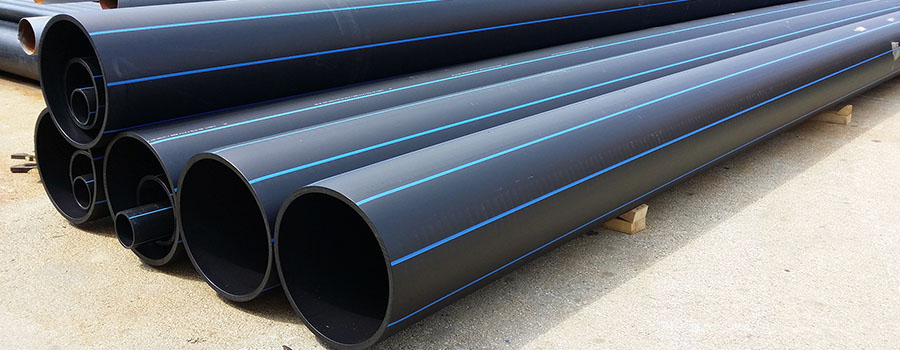

HDPE pipes are known for their high impact resistance, flexibility, and resistance to chemicals and corrosion. These features make them ideal for a wide range of applications, ensuring longevity and reliability.

Advantages of HDPE Pipes in Flow Efficiency

- Smooth Interior Surface: HDPE pipes have a smoother interior compared to traditional materials, reducing friction and improving flow capacity.

- Corrosion Resistance: Unlike metal pipes, HDPE is immune to rust and corrosion, maintaining optimal flow over time.

- Leak-Free Joints: The fusion process creates strong, seamless joints, minimizing leak risks and maintaining consistent flow.

Design Considerations for Optimal Flow

- Pipe Diameter and Wall Thickness: Selecting the appropriate diameter and wall thickness is crucial for balancing flow capacity and pressure.

- Bend Radius: HDPE’s flexibility allows for a tighter bend radius without affecting flow efficiency.

- Temperature and Pressure Ratings: Understanding the operating conditions ensures the pipe design can handle the expected load.

Case Study: Impact of HDPE Pipe Design

To illustrate the superiority of HDPE pipes in flow speed and leak prevention compared to traditional materials, we analyzed a study focused on a municipal water supply network. This study compared systems using HDPE pipes with those using traditional materials such as PVC and steel pipes.

Table: Comparison of Flow Rate Between HDPE and Traditional Pipes

| Pipe Material | Average Flow Rate (m/s) | Leakage Rate (%) | Lifespan (Years) |

| HDPE | 1.2 | <0.1 | 50 |

| PVC | 1.0 | 0.5 | 30 |

| Steel | 0.8 | 1.0 | 25 |

HDPE pipes have a higher flow rate at the initial installation compared to other materials. Over time, due to their corrosion resistance and low leakage rate, the flow rate in HDPE pipes remains stable, while the flow rate in traditional materials gradually decreases due to corrosion and leakage issues.

Through this case study, we observe the significant advantages of HDPE pipes in enhancing flow rates and reducing maintenance compared to traditional pipe materials. This is crucial for designing efficient and reliable fluid transportation systems.

Integration of Tables and Graphs

- Flow Rate Comparison: A table comparing the flow rates of HDPE pipes versus traditional pipes under various conditions.

- Cost-Benefit Analysis: A graph illustrating the long-term savings due to reduced maintenance and longer lifespan of HDPE pipes.

Latest Industry Insights

Recent advancements in HDPE technology have further enhanced their efficiency and sustainability. According to a 《hdpe pipe 2023 industry report》, there has been a notable increase in the adoption of HDPE pipes in both developed and developing regions.

HDPE pipes, with their advanced design features, offer an efficient and sustainable solution for fluid transport. By optimizing pipe design, significant improvements in flow efficiency can be achieved, benefiting a wide range of applications.