18

Nov

HDPE Pipes in Cold Climates Performance and Reliability Analysis

High-Density Polyethylene (HDPE) pipes are renowned for their durability and versatility, making them an ideal choice for water infrastructure in cold climates. This article delves into their performance and reliability in such challenging environments.

Unique Characteristics of HDPE Pipes

HDPE pipes possess unique properties that make them suitable for cold climates:

- Flexibility: Unlike traditional materials, HDPE can withstand temperature variations without cracking.

- Corrosion Resistance: HDPE is immune to rust and corrosion.

- Longevity: These pipes are known for their long service life, often exceeding 50 years.

Performance in Cold Climates

In cold climates, HDPE pipes face unique challenges:

- Thermal Expansion: HDPE expands and contracts with temperature changes. Proper installation techniques are crucial to accommodate this.

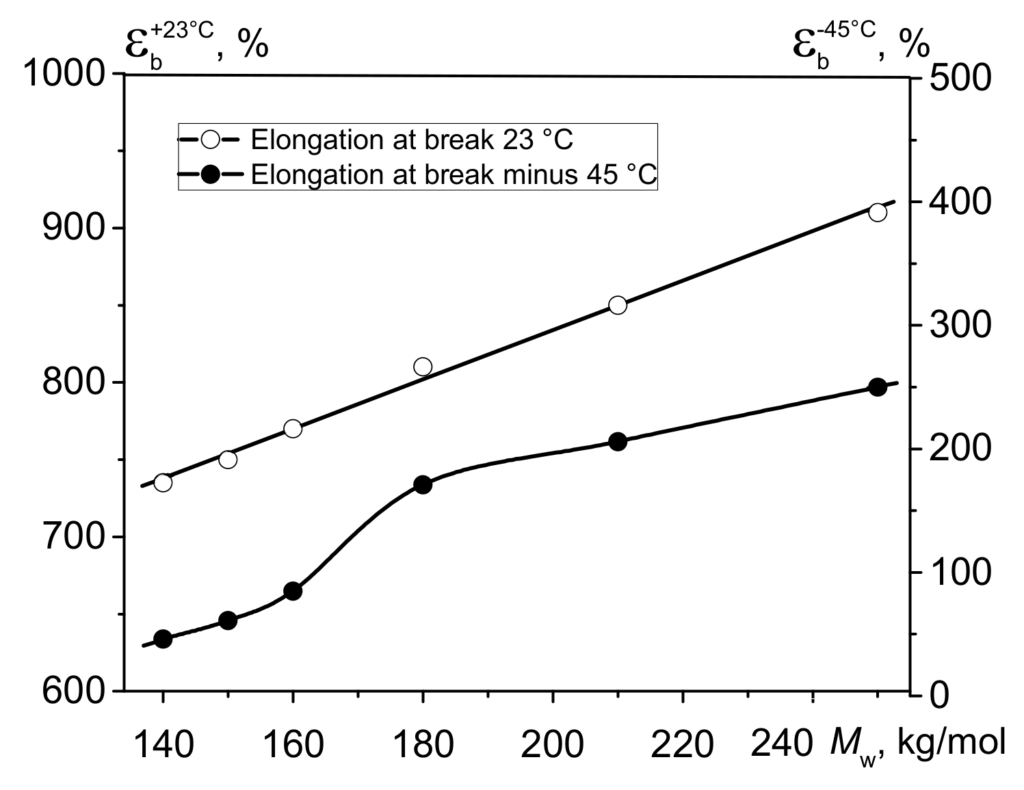

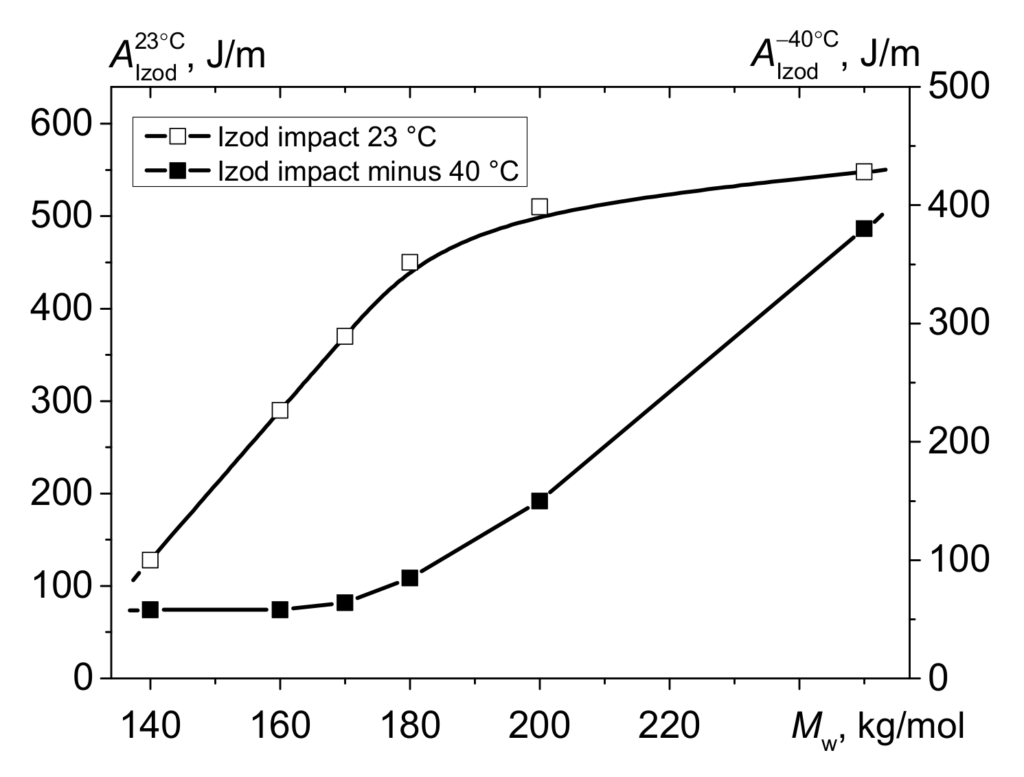

- Impact Resistance: HDPE’s toughness helps it resist impacts at low temperatures, a common occurrence in cold climates.

Installation and Maintenance in Cold Conditions

Installation and maintenance practices for HDPE pipes in cold climates require special consideration:

- Proper Bedding: Ensuring correct bedding material and compaction is crucial to prevent pipe movement.

- Use of Insulation: In extremely cold environments, additional insulation might be necessary.

Case Studies and Industry Data

Several studies highlight the effectiveness of HDPE pipes in cold climates:

- Study 1: 《Impact of Low Temperatures on HDPE Pipes》

- Study 2: 《Long-term Performance of HDPE Pipes in Cold Climates》

These studies demonstrate the resilience and efficiency of HDPE pipes in harsh conditions.

Comparative Analysis

This comparison highlights the differences between HDPE, PVC, and steel pipes, particularly focusing on their performance in cold climates:

| Feature | HDPE Pipes | PVC Pipes | Steel Pipes |

| Flexibility | High | Moderate | Low |

| Corrosion Resistance | Excellent | Good | Poor |

| Lifespan | Over 50 years | 25-40 years | 20-30 years |

| Installation Complexity | Moderate | Low | High |

| Highest Operating Temperature | 60°C (140°F) | 60°C (140°F) | 260°C (500°F) |

| Lowest Operating Temperature | -40°C (-40°F) | 0°C (32°F) | -20°C (-4°F) |

Conclusion

HDPE pipes present a reliable and efficient solution for water infrastructure in cold climates. Their unique properties and proven track record make them a superior choice for such challenging environments.

References