20

Jul

Judge The Quality Of HDPE Pipes Based On Appearance

The important parameters of HDPE pipe are ring stiffness, ring flexibility, longitudinal retraction rate, impact performance, oven test, appearance and wall thickness meet the requirements.

It is necessary to judge the quality of HDPE pipes by appearance. Generally. Judging the quality of High-Density Polyethylene (HDPE) pipes from their appearance can provide some initial insights into their overall condition and manufacturing quality. While it’s not a comprehensive assessment, observing certain visual characteristics can give you an idea of their potential suitability for a specific applicationit will be initially identified whether the purchased HDPE pipe meets the project standards from several aspects, such as Surface Finish, Color Uniformity, Transparency (if applicable), Welding or Joint Quality, Surface Contamination, Labels and Markings, Physical Integrity.

Next, this article will explain in detail the above several judgment methods, please combine your own HDPE pipe, check the comparison

Judging the Quality Of HDPE Pipes Based On Appearance

- Surface Finish: Examine the surface of the HDPE pipe. It should have a smooth, uniform finish without any visible roughness, pitting, or irregularities. A consistent and glossy appearance is generally an indicator of higher quality.

- Weight: Although a subjective test, heavier pipes of the same size and thickness may suggest denser and higher-quality HDPE material.

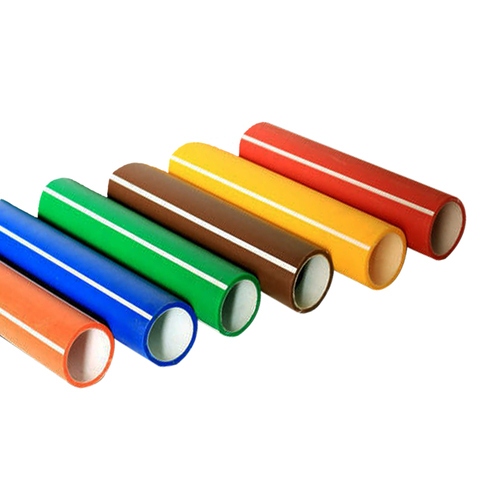

- Color Uniformity: HDPE pipes come in various colors, but regardless of the color, it should be consistent and uniform throughout the entire length of the pipe. Look for pipes with even color distribution without any noticeable variations or discolorations.

- Clarity and Transparency: For translucent HDPE pipes, check the clarity and transparency. Clear pipes should have high optical clarity without any haze, cloudiness, or visible impurities.

- Welding or Joint Quality: If the HDPE pipe has welded joints, visually inspect the quality of the welds. The joints should be smooth, consistent, and free from any visible gaps, voids, or signs of poor welding.

- Surface Contamination: Assess the pipe’s surface for any visible contamination, such as dirt, debris, or foreign particles. High-quality HDPE pipes should be clean and free from any external contaminants.

- Labels and Markings: Look for clear, legible, and properly marked labels on the pipes. The labels should include relevant information such as the manufacturer’s name, production date, size, and relevant standards compliance. Well-defined labels indicate proper quality control and attention to detail.

- Physical Integrity: Inspect the pipe for any visible physical damage, such as cracks, dents, air bubbles, or deformities. A high-quality HDPE pipe should have a structurally sound appearance without any evident imperfections.

Remember that while appearance can give you some clues about the quality of HDPE pipes, it is not a substitute for comprehensive testing and adherence to industry standards. The suggestion is combined with other quality inspections, such as material composition, manufacturing standards, compression testing, etc., for comprehensive analysis and evaluation

Be sure to purchase pipe from a reliable, quality-assured supplier and manufacturer to keep the quality of your project. When purchasing, the manufacturer can provide catalogue, technical parameters, product images, factory images, production images, customer project cases, quality certificates, etc. as references