19

Jul

How To Install Underground HDPE Pipe?

Underground HDPE pipes are widely used in water supply, fire protection, electricity, drainage, sewage, dredging, etc.

Installing an underground HDPE (High-Density Polyethylene) pipe requires careful planning and execution to ensure a reliable and long-lasting infrastructure. In this article, we will explore two popular methods for installing underground HDPE pipes: Trench Installation and HDD (Horizontal Directional Drilling) Or Directional Boring. Understanding these techniques will help you successfully install an underground HDPE pipe system. Read on to learn more about each method and their step-by-step processes.

Trench Installation

Trench installation is a traditional and widely used method method used for laying underground HDPE pipes. This process excavating a trench along the desired path, placing the pipe within the trench, and backfilling the space to secure it in place.

1.Planning and Marking

Planning the pipe route and marking the trench location. Take into account any underground utilities, obstacles, and necessary depth for the pipe installation.

2.Excavation

Manual slotting shall be carried out according to the design pile number position measured by the drawing design and the surveyor. The width of the HDPE pipe groove is slightly wider than the pipe diameter by 1~2 cm, and the groove depth is 23 cm below the surface of the road bed. The groove length requires that the inner side is 10 cm away from the center line, the outer side extends to the side slope, and the excavated section extends to the inner wall of the side ditch. The slope of the groove should follow the horizontal drainage slope of the road, and the slope should not be reversed, so as to ensure that the water in the road is discharged out of the roadbed. Pull the wire before slotting to ensure straightness.

3.Bedding Preparation

Create a stable and uniform bedding for the HDPE pipe by carefully removing any rocks, debris.

Add a layer of bedding material, such as sand or gravel, at the bottom of the trench.

Use padding material, such as sand or geotextile fabric, to surround the pipe and prevent damage caused by friction.

4.Pipe Placement

Carefully lower the HDPE pipe into the trench, Censuring it aligns with the planned route, avoiding any sharp bends or sudden drops.Make sure the pipe is properly supported and does not sag or experience excessive stress.

5. Jointing and Connection

Use appropriate joining techniques, such as butt fusion, electrofusion or fittings connectors, to securely join the HDPE pipe sections together. Avoid water leakage

6. Backfilling and Compaction

Fill the trench with the excavated fine-grained soil or sandy soil, and large stones must be removed, Backfill in layers to avoid voids or settling.manual compaction must be done after backfilling,compacting each layer thoroughly to provide stable support.The top surface of the backfill should not be higher than the road bed, and it is better to be 1~2 cm lower than the road bed surface

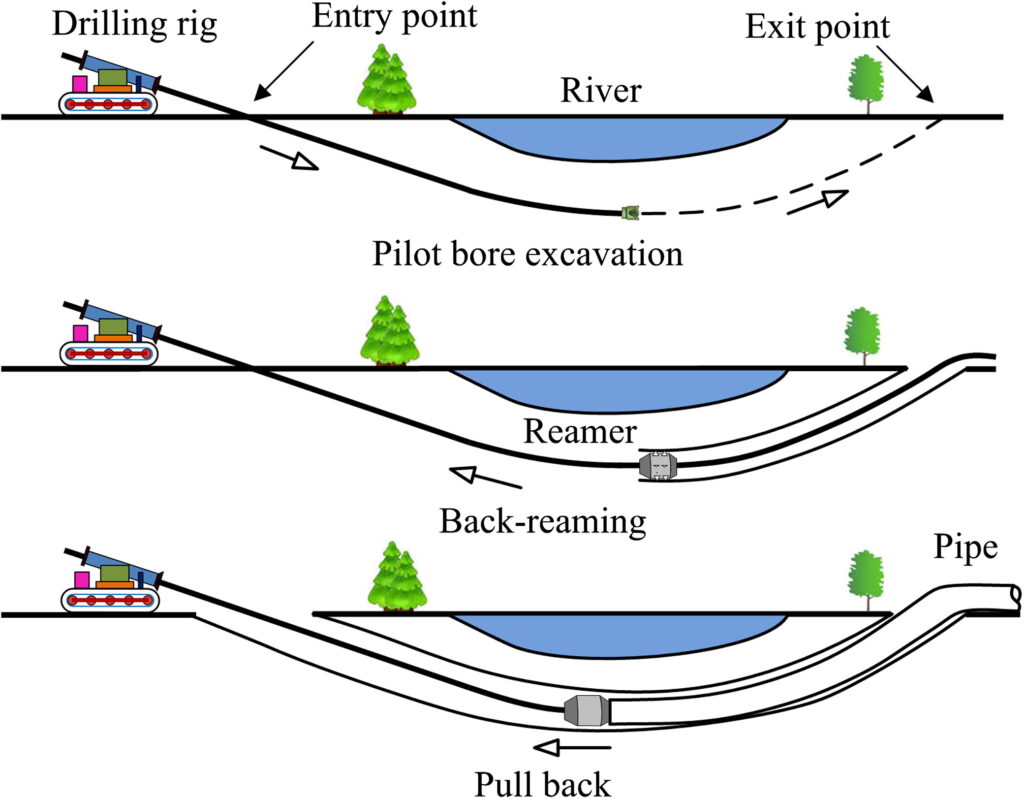

HDD (Horizontal Directional Drilling) Or Directional Boring

HDD(Horizontal Directional Drilling) or directional boring is a trenchless method, alternative to trench installation. It needs drilling underground and pulling the pipe through the drilled hole. This technique is suitable when obstacles or sensitive areas are present, minimizing surface disruption.This is especially useful when installing pipe under roadways, rivers and lakes, rail crossings, existing utility installations, or other obstacles.

- Using specialized drilling equipment, create a small pilot hole along the desired pipe route. The drill is guided horizontally underground, avoiding obstacles and sensitive areas.

- Enlarging the pilot Hole to fit pipeline,pulled into the HDPE pipe and gradually insert it into the enlarged pilot hole.

- Connect HDPE pipe sections securely and Verify the integrity of the connections to prevent leaks or failures.

- Backfill the drill path(Entrance and receiving ) and restore the surface.Take care to avoid any damage to the newly installed pipe

Proper installation of underground HDPE pipes is crucial for a reliable and long-lasting infrastructure.Whether you opt for trench installation or HDD, following the outlined steps and adhering to industry standards.

Puhui has more than 30 years of experience in pipeline production and sales, and has participated in more than 100 large, medium and small pipeline projects around the world. if you have any specific concerns or unique project requirements, please contact us