06

Jul

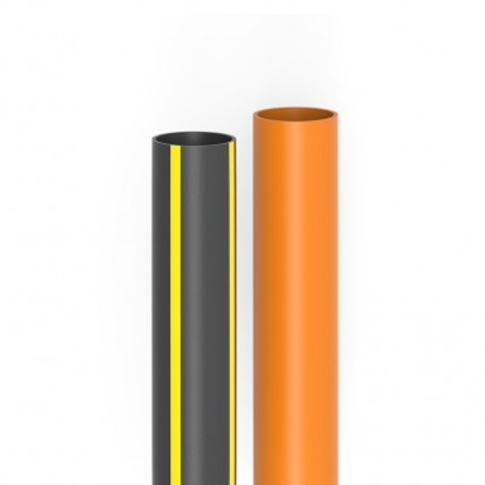

Advantages And Features Of HDPE Pipe

HDPE (High-density polyethylene) pipes are known for their high tensile strength, durability, flexibility and lightweight. Owing to the seamless nature of HDPE pipe system, HDPE offers a zero leak rate when they are fused together. What makes HDPE pipes even more favourable is the fact that they are environmentally friendly and mark sustainable footprint on earth. They are non-toxic, chemical and corrosion resistant, and have a long lifespan.

HDPE pipes are suitable for trenchless installation methods. Let’s take a closer look at their properties and advantages.

Advantages & Features

> Durability and Strength

HDPE pipe fittings are highly durable and offer excellent strength, making them suitable for both above-ground and underground installations. These fittings can withstand high-pressure applications and are resistant to cracks, leaks, and damages caused by external factors such as weather conditions or soil movement.

> High Toughness – Resistance to Rapid Cracking

HDPE pipe is a high-toughness pipe with an elongation at break of more than 500%, excellent shock resistance, and HDPE pipe has excellent resistance to rapid cracking

> Corrosion and Chemical Resistance

One of the significant advantages of HDPE pipe fittings is their resistance to corrosion and chemicals. HDPE pipes are immune to the corrosive effects of soil, water, and various chemicals, including acids, alkalis, and other aggressive substances. This makes them ideal for applications in industries such as mining, chemical processing, and wastewater treatment.

> Excellect Flow Characteristics

In addition to the smooth external surface, the pipes & ducts have an extremely smooth inner surface too.Because polyethylene is smoother than steel, cast iron, ductile iron, or concrete, a smaller PE pipe can carry an equivalent volumetric flow rate at same pressure. Offering very low frictional resistance to fluid flow.It has less drag and a lower tendency for turbulence at high flow.

> Butt Fusion Jointing Connect

HDPE pipes are heat fused together to form a joint which is stronger than the pipe itself. Electro fusion is the reliable welding technique that is used to weld HDPE. It also offers significant installation advantages when compared to traditional pipe materials.

> Flexibility and Ease of Installation

HDPE pipe fittings are highly flexible, allowing for easy installation even in challenging terrains. Their flexibility enables them to withstand ground movements and seismic activities, minimizing the risk of pipe failure. Additionally, the lightweight nature of HDPE pipes simplifies the installation process, reducing labor and equipment costs.

> Longevity and Low Maintenance

HDPE pipes have a long service life, often exceeding 50 years, which is significantly higher compared to other pipe materials. Their durability and resistance to environmental factors ensure a longer lifespan, reducing the need for frequent replacements or repairs. This ultimately leads to lower maintenance costs and increased cost-effectiveness.

> High Electrical Resistance

As the dielectric strength of HDPE is very high, the pipes are extensively used as electrical conduits. No stray electrical currents can be transmitted from outside.

HDPE pipe systems are produced in straight lengths or in coils. Made from materials that are approximately one-eighth the density of steel, they are lightweight and do not require heavy lifting equipment for installation. It reduces the need for fittings, excels in changing floors and performs well in earthquake-prone areas. HDPE resists the effects of freezing and allows bending without the need for an excessive number of fittings. Since HDPE is not a fragile material, it can be easily laid in uninterrupted lengths with bends on rough terrain.

It is preferred for trenchless technology. It is used in directional drilling, farming, river crossings, pipe blasting and lining work. HDPE performs remarkably in mining, dredging and similar applications.

HDPE pipe fittings offer numerous advantages over traditional pipe materials, making them a preferred choice in various industries. Their durability, corrosion resistance, flexibility, and ease of installation make them suitable for a wide range of applications, including water supply systems, fire fighting, electrical cover, gas distribution, and industrial settings. By understanding the full meaning of HDPE Pipe and its advantages, businesses can make informed decisions when selecting pipe fittings for their specific requirements.