31

Aug

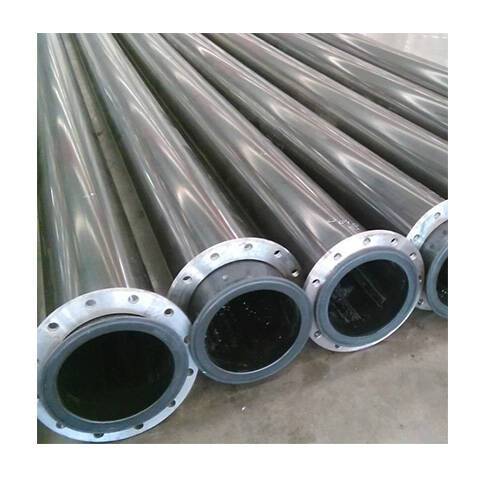

HDPE Pipe Trenchless Construction Techniques

878

HDPE pipes are commonly used for underground water and sewage transportation due to their durability and flexibility. Trenchless construction techniques are used to install these pipes without the need for open trenches and minimize disruption to the surrounding environment. Some trenchless construction techniques for HDPE pipes include:

- Horizontal Directional Drilling (HDD): This technique involves drilling a pilot hole at a predetermined depth and alignment. The HDPE pipe is then pulled through the drilled hole using a drill rig and high tensile strength pulling equipment. HDD is suitable for installing HDPE pipes under obstacles such as roads, rivers, and existing infrastructure.

- Pipe Bursting: Pipe bursting involves breaking the existing pipeline while simultaneously pulling in a new HDPE pipe behind it. A bursting tool is inserted into the existing pipe, which fractures it and pushes the fragmented pieces into the surrounding soil. The new HDPE pipe is then pulled into place as the bursting tool progresses. Pipe bursting is useful for replacing old and damaged pipes.

- Slip Lining: Slip lining is the process of inserting a smaller diameter HDPE pipe into a larger existing pipe. The annular space between the pipes is usually filled with grout or a lubricant. Slip lining is suitable for rehabilitating existing pipelines and can improve flow capacity without requiring a full replacement.

- Direct Pipe Method: The direct pipe method combines the use of a microtunneling machine and a pipe thruster. A pilot tunnel is excavated using a remote-controlled tunneling shield, while the HDPE pipe is simultaneously pushed into the tunnel. The tunneling shield provides support to the excavation and maintains a stable tunnel. This technique is suitable for a variety of ground conditions.

These trenchless construction techniques for HDPE pipes offer several advantages, including reduced cost, minimized environmental impact, faster installation, and decreased disruption to traffic and nearby structures. However, the suitability of a specific technique depends on factors such as pipe diameter, soil conditions, length of the installation, and project requirements.

Previous post: