01

Sep

What Requirements Should Be Met When Purchasing HDPE Pipes?

In our life and production, HDPE pipe is a commonly used pipe and is widely used in water supply, fire protection, irrigation, drainage, sewage, electricity, dredging, mining, etc. The quality of the tube is critical to the project. Next, let’s take a look at what requirements you need to meet when purchasing this type of pipe.

1. Check whether the product has a factory certificate and factory inspection report.

2. Check the appearance. Check whether the inner and outer surfaces of the pipe are clean and smooth, and whether there are grooves, paint, dents, impurities, and uneven colors.

3. Length check. The length of the pipe should be uniform, and the error should not exceed plus or minus 20mm. Check whether the nozzle end face is perpendicular to the axis of the pipe and whether there are air holes. All pipes of different lengths will not be accepted until the cause is determined.

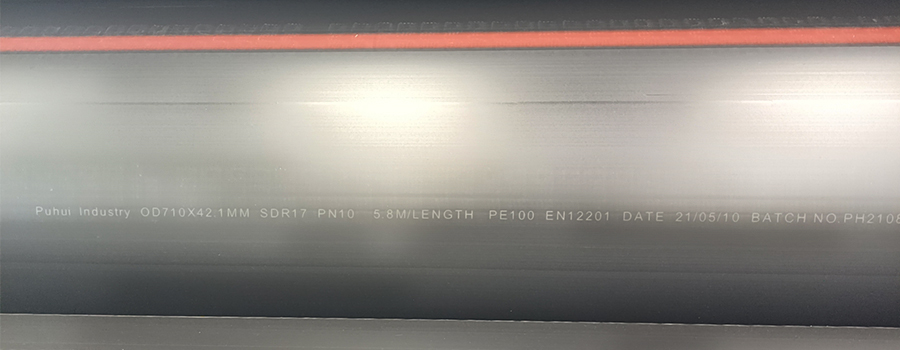

4. Clear and unambiguous marking. When it is black, the nozzle must have eye-catching color bars. At the same time, there should be continuous permanent marks on the pipe with a spacing of no more than 2m, [indicating the purpose, raw material brand, standard size ratio, specification size, standard code and number, manufacturer’s name or trademark, and production date].

5. Out-of-roundness test: Take the arithmetic mean of the experimental results of three samples as the out-of-roundness of the pipe. If the value is greater than 5%, it is a failure.

6. Inspection of pipe diameter and wall thickness. Checking the pipe diameter is done with a round ruler, measuring the diameter at both ends of the pipe. Any nonconformity is considered a failure. The double thickness inspection is carried out with a micrometer, measuring the upper and lower four points of the circumference. Unqualified parts cannot be used.