17

Jul

HDPE Pipe Production Process and Precautions

High-Density Polyethylene (HDPE) pipes are widely used in various industries for their durability, flexibility, and resistance to corrosion.

This article will provide a comprehensive step-by-step guide to the HDPE pipe production process and precautions during operation, shedding light on the key stages involved. From raw materials to finished products, we will delve into each step, highlighting the significance and techniques employed to manufacture top-quality HDPE pipes.

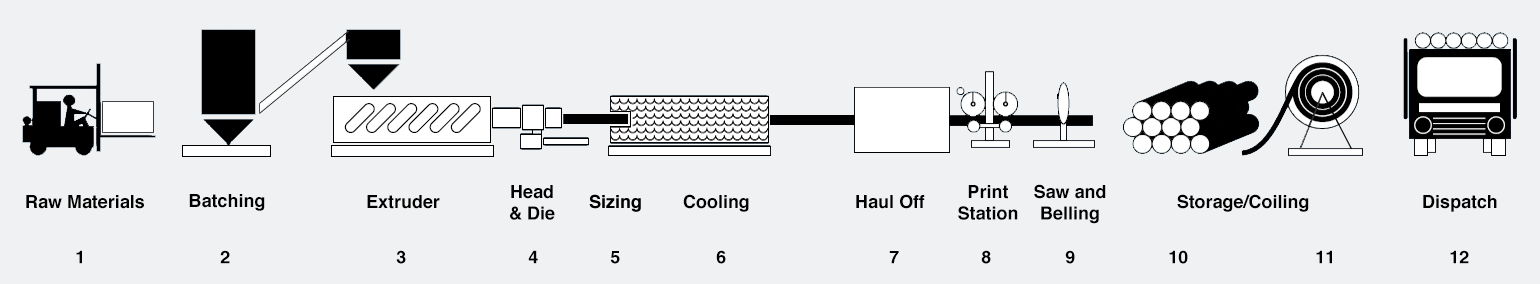

HDPE Pipe Production Process 7 Step

1. Raw Material Preparation And Drying

The first step in the HDPE pipe production process is selecting the high-quality raw materials. The material must meet stringent quality standards to ensure the resulting pipes have the desired properties, such as high tensile strength, chemical resistance, and longevity.

The selected HDPE resin is then thoroughly dried to eliminate moisture and impurities, ensuring optimal pipe strength.

2. Plastic & Extrusion

The extrusion process is the heart of HDPE pipe production. Raw materials enter the extruder from the hopper, and are transported, compressed, melted and homogenized, and then transforming it into a continuous hdpe pipe profile.

Size, thickness, and color customization can be achieved at this stage, depending on customer specific project requirements.

3. Cooling and Sizing

After extrusion, the newly formed HDPE pipe passes through a cooling chamber. This chamber utilizes a cooling medium, such as water or air, let the high-temperature hdpe pipe is rapidly cooled, solidifying its shape. The controlled cooling process ensures dimensional stability and prevents any deformation or warping.

Simultaneously, sizing tools are employed to ensure the pipe achieves the exact dimensions specified. This step is crucial for maintaining uniformity and accuracy throughout the production process.

4. Marking and Printing

Once the HDPE pipes are cooled and sized, they undergo marking and printing procedures. Information such as manufacturer’s name, pipe size, and relevant standards are imprinted on the pipe surface using automated printing machines. This ensures easy identification, traceability, and compliance with industry regulations.

5. Pipe Cutting

Under the control of the meter wheel, the fixed-length cutting of the pipe is completed by the planetary cutting machine. Due to the size limit of the container, usually the length of HDPE pipe is 5.8m or 11.8m, coil lenth is 100m-200m a roll

6. Quality Control and Testing

Ensuring the highest quality standards is paramount in HDPE pipe production. Comprehensive quality control measures are implemented at various stages of the manufacturing process. Such as hydrostatic pressure testing, conducted to assess strength, impact resistance, pressure capacity, and overall performance. Dimensional inspection, material analysis and Quality control measures are implemented to identify and rectify any defects are performed to verify the pipes’ compliance with industry standards and specifications.

7. Coiling and Packaging

The packaging is designed to safeguard the pipes from external elements and ensure their safe delivery to the end-users. Proper labeling is applied to identify the pipe specifications and facilitate easy handling and storage.

Precautions during Production

- The suction time should not be too long; clean the filter screen frequently; monitor whether the micro switch is normal

- Dryer first turn on the fan and then turn on the heating

- The best drying effect can be achieved only when the dryer is full

- Control the direction of air movement

- The air inlet of the dryer must not be closed

The HDPE pipe production process involves a series of meticulously executed steps to manufacture high-quality pipes that meet industry standards. From material selection and extrusion to cooling, sizing, marking, and quality control, every stage plays a crucial role in ensuring the durability and reliability of the final product.

If you have related pipeline projects, whether it is water supply, fire protection, drainage, sewage, electricity, communication, irrigation, dredging, you can choose HDPE pipes. If you have more questions, please contact us