15

Jun

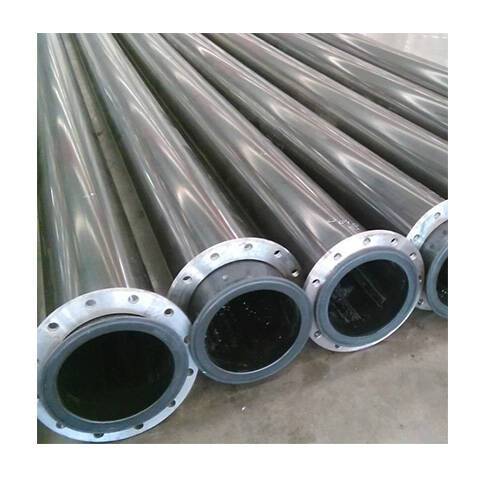

HDPE pipe For Sustainability

The benefits of HDPE pipe systems were demonstrated in Kobe, Japan during the earthquake of 1995 when 6,000 people perished and nearly half a million homes were destroyed. Osaka gas found failures in their steel and iron systems; but none where HDPE pipe was installed. For these reasons, Japan has been systematically replacing pipelines with HDPE throughout the country wherever and whenever possible.

Other characteristics make HDPE pipe an ideal choice as well. Superior properties including abrasion and rust resistance, cost effectiveness, zero-leak capability and ease of installation earn it top rank as material-of-choice for gas companies worldwide. Today 95% of all gas service lines in North America count upon HDPE pipe’s reliable systems. And nuclear power plants are be- ginning to transition to HDPE pipe use for safety and non-safety applications as the preferred option for new facilities. These critical-use applications rely on the steadfast ability of HDPE pipe systems to supply steady operation. HDPE pipe systems can sustain your city’s most unsuspected upheaval during earthquakes and can provide a lifeline in their aftermath.

HDPE PIPE — EARTHQUAKE SIMULATION TESTED

In addition to being tested during actual earthquakes throughout the US, Canada and the globe, Cornell University researchers simulated, on April 6, 2006, an earthquake’s effects on gas and water polyethylene (PE) pipes by exerting a 120,000-pound force on a 16-inch diameter, 35-foot-long pipe – the largest test of ground rupture effects that has ever been performed in a lab. The PE pipe, buried three feet below the surface, did not break during the test, but the sand shifted, bulged and cracked and created webbed lines on the surface as the pipe bent. Dur- ing real life catastrophes PE pipe can be expected to perform well, while other pipe materials will be far more susceptible to breakage and lapse of service.

HDPE PIPE IS:

- A LEAK-PROOF SYSTEM – heat fused joints are as strong or stronger than the pipe itself and provide uninterrupted flow.

- FLEXIBLE AND DURABLE – HDPE pipes are strong but pliable and well suited for dynamic applications including areas prone to seismic activity.

- RUST-PROOF AND IMPERVIOUS TO BUILD-UP – does not support biological growth, provides no host for nutrients for bacterial or fungal growth and is the material of choice in harsh chemical environments.

- ABRASION RESISTANT – does not easily pit, scratch or puncture.

- LIGHT WEIGHT – easier to handle and install than rigid metallic or concrete pipe segments, allowing for huge cost advantages in the construction process.

- COST EFFECTIVE – long term cost advantages due to its physical properties, leak free joints and reduced maintenance costs.

HDPE PIPE FOR SUSTAINABILITY

HDPE pipe systems provide communities and municipalities with sustainable solutions for infrastructure. Due to the absence of joints, HDPE provides a leak-free pipe system that eliminates water loss, conserves natural resources, eliminates infiltration and ex-filtration of contaminants and allows the use of cost-effective trenchless construction methods that are less disruptive to the surrounding environment.

HDPE pipe helps protect communities in the most unsettling of circumstances – earthquakes and ground movements – and mayors nationwide, along with their staff who make installation of HDPE pipe systems a priority are heroes for protecting their constituents.