06

Dec

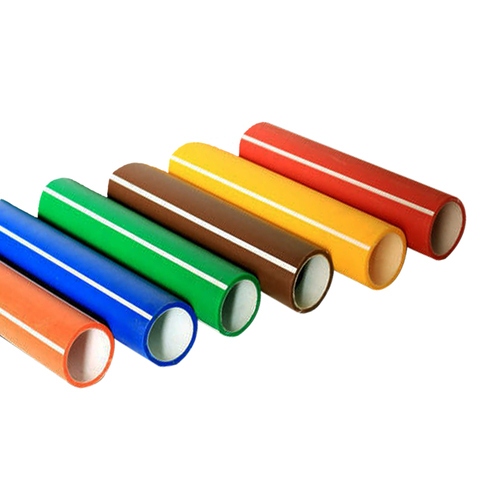

What Kind Of Pipe is Used For Electrical Conduit?

Electrical conduits are essential in the safe and efficient management of wiring in various construction projects, ranging from residential buildings to large commercial structures. They provide a robust and secure pathway for electrical wiring, protecting it from damage, environmental factors, and ensuring compliance with safety standards. Among the various materials used for electrical conduits, High-Density Polyethylene (HDPE) electrical conduit pipes have gained prominence due to their unique properties and advantages.

Advantages of HDPE Electrical Conduit Pipes

- Durability and Strength: HDPE is known for its high strength-to-density ratio, making it highly durable and suitable for both rigorous underground and surface installations. This robustness ensures a longer lifespan for the conduit system.

- Corrosion Resistance: Unlike metal conduits, HDPE is resistant to a wide range of chemical agents and does not corrode. This feature makes it ideal for installations in areas prone to chemical exposure or high moisture.

- Flexibility and Lightweight: HDPE pipes are more flexible compared to rigid metal conduits. This flexibility allows for easier installation, especially in areas with complex layouts. Additionally, being lightweight, they are easier to transport and handle on site, reducing installation costs.

- Electrical Insulation: HDPE provides excellent electrical insulation. This property is critical in preventing electrical hazards and ensuring the safety of the conduit system.

- Environmental Resistance: HDPE conduits can withstand extreme environmental conditions, including temperature fluctuations and UV exposure, making them suitable for a wide range of climates.

- Cost-Effective: Despite their high quality and longevity, HDPE electrical conduits are cost-effective, offering a financially viable option for both small-scale and large-scale projects.

Comparison with Other Conduit Types

While the article 《8 Types Of Electrical Conduit And Uses For Construction Projects》provides an extensive overview of various conduit types, including metallic options like Rigid Metal Conduit (RMC), Galvanized Rigid Conduit (GRC), and non-metallic choices like PVC and ENT, HDPE stands out for its specific use-cases and advantages. For instance, while metal conduits offer great protection and durability, they are prone to corrosion and are often heavier, making them less ideal for certain installations. On the other hand, PVC conduits, though lightweight and corrosion-resistant, may not offer the same level of durability and flexibility as HDPE conduits in certain environments.

Applications of HDPE Electrical Conduit Pipes

- Underground Installations: Their corrosion resistance and strength make them perfect for burying underground, where moisture and chemical exposure are common.

- Industrial Applications: In industries where chemical exposure is a concern, HDPE conduits offer reliable protection for electrical wiring.

- Residential and Commercial Buildings: For buildings with complex wiring needs, the flexibility and ease of installation of HDPE conduits make them a suitable choice.

Conclusion In summary, when considering what kind of pipe is used for electrical conduit, HDPE electrical conduit pipes present a compelling choice. Their durability, flexibility, corrosion resistance, and cost-effectiveness make them suitable for a wide range of applications, from residential to industrial settings. As the construction industry continues to evolve, the use of HDPE in electrical conduits is likely to increase, offering a modern solution to traditional electrical installation challenges.