14

Nov

Temperature Adaptability of HDPE Electrical Conduit Pipe

In the realm of electrical infrastructure, the significance of robust and durable conduit systems cannot be overstated. Among the various materials employed, High-Density Polyethylene (HDPE) stands out for its remarkable properties. This article delves into the temperature adaptability of HDPE electrical conduit pipes, a key factor influencing their performance and longevity.

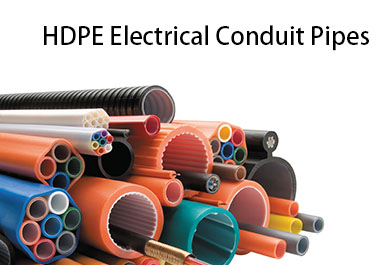

Understanding HDPE Electrical Conduit Pipes

HDPE, known for its high strength-to-density ratio, is a thermoplastic polymer produced from ethylene. Its electrical conduit pipes are widely used for protecting cables and electrical wiring in a vast array of settings, from residential buildings to complex industrial environments.

The Essence of Temperature Adaptability

Temperature adaptability refers to a material’s ability to maintain its integrity and function across a range of temperatures. For electrical conduits, this characteristic is critical, as they often face diverse environmental conditions.

How HDPE Pipes Manage Temperature Variations

HDPE’s molecular structure, characterized by its long, linear chains, contributes significantly to its thermal resilience. This molecular makeup endows HDPE pipes with a unique combination of flexibility and toughness, enabling them to withstand temperature fluctuations.

Key Attributes:

- Low Thermal Conductivity: HDPE has a low thermal conductivity, reducing the risk of overheating in conduits.

- High Melting Point: The melting point of HDPE typically ranges around 120°C to 180°C, which is beneficial in high-temperature environments.

- Thermal Expansion: HDPE expands and contracts with temperature changes, but its flexibility prevents damage under normal environmental conditions.

Comparative Analysis

A comparison with other materials such as PVC and metal highlights HDPE’s superior temperature adaptability. The following table illustrates these differences:

| Material | Thermal Conductivity (W/mK) | Melting Point (°C) | Notable Feature |

| HDPE | 0.45-0.52 | 120-180 | High Flexibility, Low Conductivity |

| PVC | 0.19-0.16 | 75-90 | Susceptible to Brittleness at Low Temperatures |

| Metal | 50-400 | Varied | High Conductivity, Susceptible to Corrosion |

Applications and Real-World Scenarios

HDPE electrical conduits are ideal for regions experiencing extreme temperature variations. For example, in desert climates, where day and night temperatures vary drastically, HDPE’s flexibility and thermal resistance ensure continued protection of electrical wiring.

Complying with Industry Standards

Manufacturers of HDPE pipes adhere to strict industry standards, such as those set by the American National Standards Institute (ANSI) and the National Electrical Code (NEC). These standards ensure that the pipes are suitable for a wide range of temperatures.

Innovations and Industry Data

Recent advancements in HDPE technology focus on enhancing temperature resistance further. Industry reports, such as those by the Plastics Pipe Institute (PPI), provide valuable insights into these innovations. 《PPI Report on HDPE Pipes》.

Conclusion

HDPE electrical conduit pipes, with their remarkable temperature adaptability, represent a superior choice for electrical infrastructure. This adaptability, coupled with other inherent benefits such as chemical resistance and ease of installation, makes HDPE an invaluable material in the electrical industry.