04

Nov

Complete Guide to HDPE Electrical Conduit Pipe and Specifications

HDPE electrical conduit pipe is a flexible, durable material that is an excellent choice for power systems and cable protection. This article delves into the many merits of HDPE electrical conduit pipe, hdpe electrical conduit specifications, and useful application tips to ensure the right choice for your project.

What is HDPE Electrical Conduit Pipe?

HDPE electrical conduit pipe is a type of plastic pipe that houses and protects electrical wiring. It’s made from high-density polyethylene, a material known for its high strength-to-density ratio, making it a superior choice for conduit applications.

HDPE electrical conduit pipe is available in straight pipe and coiled pipe. The main difference is the size and pressure. Small size pipes can be rolled into a roll of 100-200 meters

HDPE Electrical Conduit Pipe Specifications

– Size: The diameter of the conduit pipe typically ranges from 20mm-355mm, 1/2 inch – 14 inches.

– Wall Thickness: Depending on the size and the intended application, the wall thickness can vary.

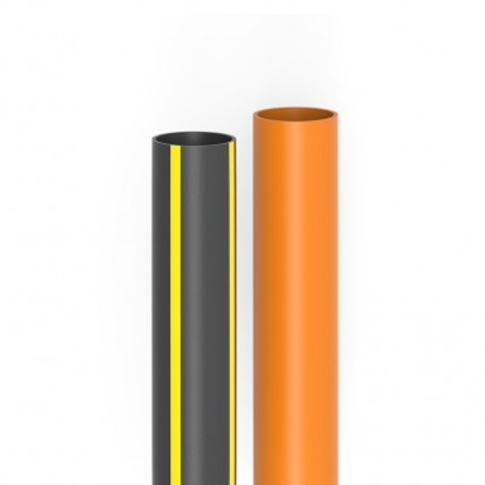

– Color: While black is the most common color, other colors can be used to differentiate between different types of wiring.

Here’s a simple table to provide a brief overview:

| Size (in inches) | Size(in mm) | Typical Wall Thickness (in mm) | Common Colors |

| 1/2 inch – 12inch | 20mm-315mm | 1.5mm-21mm | Black, Red, Blue, Yellow |

Get More details about HDPE Electrical Conduit Pipe Specifications , please check this page

| Nominal Pressure PE 100 |

SDR 11 | SDR 13.6 | SDR 17 | SDR 21 | SDR 26 | SDR 33 |

| PN 16 | PN 12.5 | PN 10 | PN 8 | PN 6 | PN 5 | |

| Nominal Size DN (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) |

| 20 | 2.0 | – | – | – | – | – |

| 25 | 2.3 | 2.0 | – | – | – | – |

| 32 | 3.0 | 2.4 | 2.0 | – | – | – |

| 40 | 3.7 | 3.0 | 2.4 | 2.0 | – | – |

| 50 | 4.6 | 3.7 | 3.0 | 2.4 | 2.0 | – |

| 63 | 5.8 | 4.7 | 3.8 | 3.0 | 2.5 | – |

| 75 | 6.8 | 5.6 | 4.5 | 3.6 | 2.9 | – |

| 90 | 8.2 | 6.7 | 5.4 | 4.3 | 3.5 | – |

| 110 | 10.0 | 8.1 | 6.6 | 5.3 | 4.2 | – |

The Advantages of HDPE Electrical Conduit Pipe

1. Durability: HDPE is resistant to impact, weather, chemicals, and UV radiation, making it exceptionally durable

2. Flexibility: Due to its flexible nature, HDPE conduit pipe can be installed in a variety of environments, including uneven terrains.

3. Cost-Effective: When considering the long-term maintenance costs, HDPE conduit pipe is often more cost-effective than its counterparts.

Practical Applications of HDPE Electrical Conduit Pipe

– Residential Buildings: For wiring in homes and apartments, HDPE conduit pipe offers a safe, durable, and cost-effective solution.

– Commercial Buildings: These pipes are used in office buildings, shopping malls, and other commercial structures.

– Industrial Applications: Given their resistance to harsh environments, these pipes are ideal for industrial settings.

In conclusion, HDPE electrical conduit pipe, with its impressive specifications and benefits, is a solid choice for your electrical wiring needs. Its durability, flexibility, and cost-effectiveness make it desirable for a variety of applications.Understanding the specifications and capabilities of HDPE electrical conduit pipes will enable you to choose the right product for your project. Whether you’re wiring a small residential building or a large industrial complex, HDPE conduit pipe is a reliable, high-quality choice.

Order HDPE Electrical Conduit Pipe Please Contact Puhui Now! You will Get quote today!