To All Customers Worldwide.

Get Quote: [email protected]

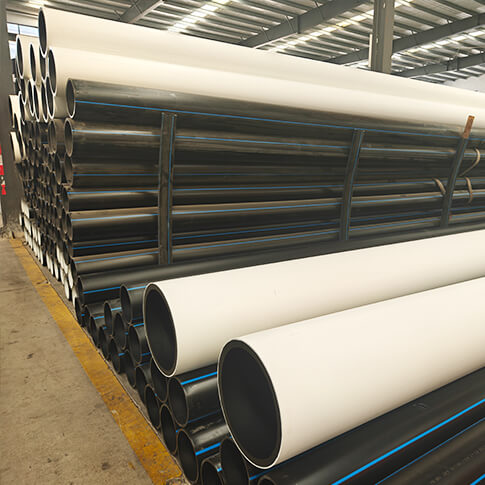

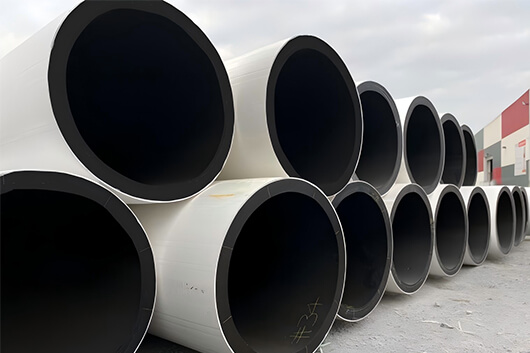

Co-Extruded White HDPE Pipe is manufactured using advanced co-extrusion technology. Unlike traditional single-layer HDPE pipes, this co-extruded variant consists of multiple layers of different materials. The outer layer is specifically formulated with materials that provide added functionalities, such as UV resistance or chemical corrosion resistance, while the inner layer retains the inherent properties of high-density polyethylene (HDPE). This manufacturing process not only preserves the excellent physical and chemical properties of HDPE but also enhances the pipe’s functionality with additional features. This innovative approach ensures that the Co-Extruded White HDPE Pipe offers superior performance while meeting diverse application needs.

√ Robust Mechanical Properties: This manufacturing technique ensures high toughness and excellent low-temperature impact resistance, while also providing superior wear resistance and corrosion resistance.

√ Exceptional Chemical Stability: The pipe exhibits outstanding chemical stability, capable of resisting corrosion from most acids, bases, and organic solvents, making it ideal for harsh chemical environments.

√ Enhanced UV Resistance: The outer white layer of the pipe is designed to reflect more ultraviolet light, significantly reducing material degradation caused by prolonged exposure to sunlight.

√ Improved Visibility: The white color of the pipe makes it visually more prominent, which is particularly beneficial in applications where easy identification is crucial.

» Chemical Plant Wastewater

» Mine Drainage

» Mine Slurry Transportation

» Seawater Desalination

» Municipal Water Supply

» Municipal Drainage

» Large-Scale Agricultural irrigation

Puhui HDPE pipe is durable, cost-effective, resistant to corrosion and can be joined through heat fusion techniques to create leak-free systems. At Puhui Pipe, we specialize in creating the ideal piping solution, offering high quality, reliable HDPE pipe for a wide variety of industries and applications, including:

If you have any inquiry about HDPE Pipe and Fittings, Contact Us Now! Get A Free Quote Quickly!

Please Contact us to Get More Details or Price, Send Email: [email protected] or WhatsApp:+86 15093100892 .

Welcome customers to visit the factory, or third party factory inspection is acceptable.

| Nominal Pressure PE 100 |

SDR 7.4 | SDR 9 | SDR 11 | SDR 13.6 | SDR 17 | SDR 21 | SDR 26 | SDR 33 |

| PN 25 | PN 20 | PN 16 | PN 12.5 | PN 10 | PN 8 | PN 6 | PN 5 | |

| Nominal Size DN (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) | Min Wall (mm) |

| 20 | 3.0 | 2.3 | 2.0 | – | – | – | – | – |

| 25 | 3.5 | 3.0 | 2.3 | 2.0 | – | – | – | – |

| 32 | 4.4 | 3.6 | 3.0 | 2.4 | 2.0 | – | – | – |

| 40 | 5.5 | 4.5 | 3.7 | 3.0 | 2.4 | 2.0 | – | – |

| 50 | 6.9 | 5.6 | 4.6 | 3.7 | 3.0 | 2.4 | 2.0 | – |

| 63 | 8.6 | 7.1 | 5.8 | 4.7 | 3.8 | 3.0 | 2.5 | – |

| 75 | 10.3 | 8.4 | 6.8 | 5.6 | 4.5 | 3.6 | 2.9 | – |

| 90 | 12.3 | 10.1 | 8.2 | 6.7 | 5.4 | 4.3 | 3.5 | – |

| 110 | 15.1 | 12.3 | 10.0 | 8.1 | 6.6 | 5.3 | 4.2 | – |

| 125 | 17.1 | 14.0 | 11.4 | 9.2 | 7.4 | 6.0 | 4.8 | – |

| 140 | 19.2 | 15.7 | 12.7 | 10.3 | 8.3 | 6.7 | 5.4 | – |

| 160 | 21.9 | 17.9 | 14.6 | 11.8 | 9.5 | 7.7 | 6.2 | – |

| 180 | 24.6 | 20.1 | 16.4 | 13.3 | 10.7 | 8.6 | 6.9 | – |

| 200 | 27.4 | 22.4 | 18.2 | 14.7 | 11.9 | 9.6 | 7.7 | – |

| 225 | 30.8 | 25.2 | 20.5 | 16.6 | 13.4 | 10.8 | 8.6 | – |

| 250 | 34.2 | 27.9 | 22.7 | 18.4 | 14.8 | 11.9 | 9.6 | – |

| 280 | 38.3 | 31.3 | 25.4 | 20.6 | 16.6 | 13.4 | 10.7 | – |

| 315 | 43.1 | 35.2 | 28.6 | 23.2 | 18.7 | 15.0 | 12.1 | 9.7 |

| 355 | 48.5 | 39.7 | 32.2 | 26.1 | 21.1 | 16.9 | 13.6 | 10.9 |

| 400 | 54.7 | 44.7 | 36.3 | 29.4 | 23.7 | 19.1 | 15.3 | 12.3 |

| 450 | 61.5 | 50.3 | 40.9 | 33.1 | 26.7 | 21.5 | 17.2 | 13.8 |

| 500 | – | 55.8 | 45.4 | 36.8 | 29.7 | 23.9 | 19.1 | 15.3 |

| 560 | – | 62.5 | 50.8 | 41.2 | 33.2 | 26.7 | 21.4 | 17.2 |

| 630 | – | 70.3 | 57.2 | 46.3 | 37.4 | 30.0 | 24.1 | 19.3 |

| 710 | – | 79.3 | 64.5 | 52.2 | 42.1 | 33.9 | 27.2 | 21.8 |

| 800 | – | 89.3 | 72.6 | 58.8 | 47.4 | 38.1 | 30.6 | 24.5 |

| 900 | – | – | 81.7 | 66.1 | 53.3 | 42.9 | 34.4 | 27.6 |

| 1000 | – | – | 90.2 | 73.5 | 59.3 | 47.7 | 38.2 | 30.6 |

| 1200 | – | – | – | 88.2 | 71.1 | 57.2 | 45.9 | 36.7 |

| 1400 | – | – | – | 102.9 | 83.0 | 66.7 | 53.5 | 42.9 |

| 1600 | – | – | – | 117.5 | 94.8 | 76.2 | 61.2 | 49.0 |

| 1800 | – | – | – | – | 106.6 | 85.8 | 68.8 | 55.1 |

| 2000 | – | – | – | – | 118.5 | 95.3 | 76.4 | 61.2 |