22

Sep

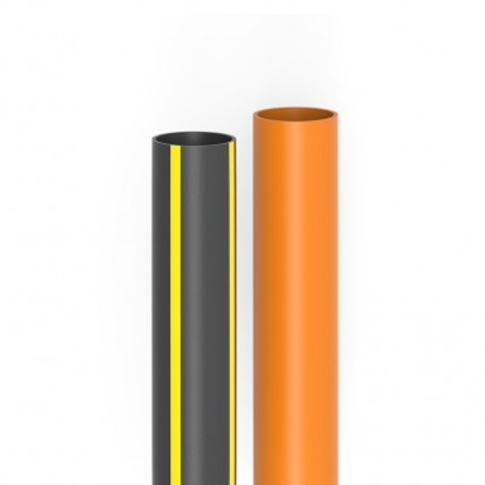

How HDPE Gas Pipes Withstand The Elements?

HDPE (High-Density Polyethylene) gas pipes are a popular choice for gas distribution networks due to their exceptional durability and resistance to environmental factors. In this article, we will explore how HDPE gas pipes withstand the elements, highlighting their unique features that make them a reliable choice for gas distribution networks.

How HDPE Gas Pipes Withstand The Elements?

Resistance to Corrosion

HDPE gas pipes are highly resistant to corrosion, making them ideal for underground gas distribution networks. Unlike metallic pipes, HDPE pipes do not rust or corrode, ensuring a prolonged service life even in harsh soil conditions. This resistance to corrosion also reduces the risk of leaks and gas contamination, ensuring a safe and secure gas supply system.UV Resistance

HDPE gas pipes are also resistant to UV radiation, making them suitable for above-ground gas distribution networks. The pipes’ unique molecular structure allows them to withstand prolonged exposure to sunlight without degrading or becoming brittle. This makes HDPE pipes an ideal choice for gas distribution networks in areas with high sun exposure.

Flexibility and Ductility

HDPE gas pipes are highly flexible and ductile, allowing them to withstand ground movement and seismic activities. This flexibility also makes them easy to install, as they can be easily maneuvered around obstacles and bent to follow the contours of the land. Additionally, HDPE pipes have a high resistance to slow crack growth, ensuring a secure gas supply system.

Low Maintenance Requirements

HDPE gas pipes have low maintenance requirements, reducing the need for frequent repairs and replacements. Their resistance to corrosion and UV radiation, coupled with their flexibility and ductility, ensures a prolonged service life with minimal maintenance. This results in cost savings over the system’s lifecycle, making HDPE pipes a cost-effective choice for gas distribution networks.

Leak-Tight Joints

HDPE gas pipes have leak-tight joints, ensuring a secure gas supply system. These pipes can be easily fused together using heat fusion techniques, resulting in a seamless and leak-free joint. This eliminates the risk of gas leaks, reducing the environmental impact and ensuring the safety of gas distribution networks.

Environmental Sustainability

HDPE gas pipes are environmentally friendly due to their recyclable nature. These pipes are commonly made from post-consumer recycled materials, contributing to the reduction of landfill waste and the conservation of natural resources. Additionally, their leak-tight joints prevent the escape of gas, reducing greenhouse gas emissions and environmental impact.

Due to their exceptional durability and resistance to environmental factors. With their resistance to corrosion, UV radiation, flexibility, ductility, low maintenance requirements, leak-tight joints, and environmental sustainability.HDPE gas pipes are a reliable choice for gas distribution networks

A reliable and efficient gas supply system while minimizing costs and environmental impact. Upgrade your gas distribution infrastructure with HDPE gas pipes and experience the transformative benefits firsthand.