10

Jul

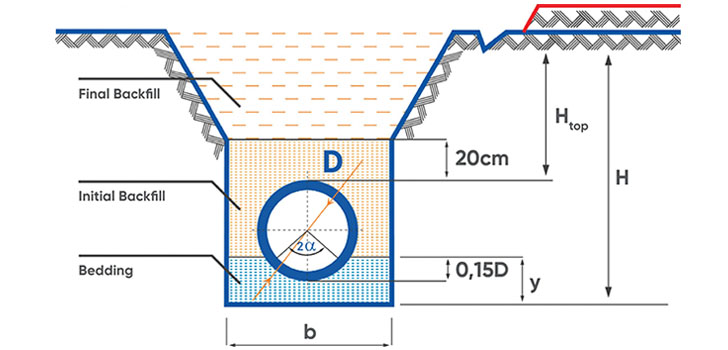

HDPE Pipe Excavation And Installation Technology

As a new type of water pipe material, HDPE pipe has better advantages. Because it can be used as both a hot water pipe and a cold water pipe, and it is easy to install. Especially as drinking water pipes, HDPE pipes are relatively green and healthy. Because the HDPE pipe used is a very wide application field of trenchless pipe laying technology, it is mainly used for the laying, replacement and repair of various underground pipes. With the continuous maturity of non-excavation technology and the continuous improvement of construction technology and equipment, its application fields are also continuously expanded.

In order to improve the welding performance of HDPE pipe, the welding surface of the pipe needs to remove the oxide layer. When operating HDPE pipe, it is advisable to use a hand scraper (glass sheet). Since the small-caliber pipe wall of the pipe is thin, it is enough to remove the oxide layer. Attention should be paid to the operation details to improve the efficiency of construction. In order to improve the use effect of HDpe pipes and ensure the construction quality, we must pay attention to the skills and methods in the treatment of oxidized pipes, so as not to expose the copper wire in the pipes, causing damage and affecting the use effect.

According to the diameter and number of HDPE pipes to be laid, the smaller diameter of the hole to be formed should be neither too large nor too small. It will increase the resistance of the pipe, causing the pipe to be detached or the HDPE pipe to be deformed. When the damaged part of the outer wall of the HDPE pipe is broken or the hole is less than 100mm in length, use a scraper to completely remove the broken pipe wall or hole, clean it with cyclohexanone within 50mm around the removed part, and brush with a plastic adhesive with good water resistance.

The cause of pitting in HDPE pipes, in order to avoid some situations, first of all, standardize the steps in the production process, select qualified raw materials, and do a good job in the maintenance of pipes. In addition, it is also the same in use, keep dry and avoid Corrosion of other special substances, etc. It is required that the factory product certificate and relevant materials of the pipeline are complete, and it can be used only after passing the inspection. Before the pipeline is transported and after it is transported to the site, the pipelines shall be inspected one by one according to the standard. Check that the quality of the inner surface, outer surface and joints of pipes and fittings should meet the requirements and there is no sign of damage.