17

Apr

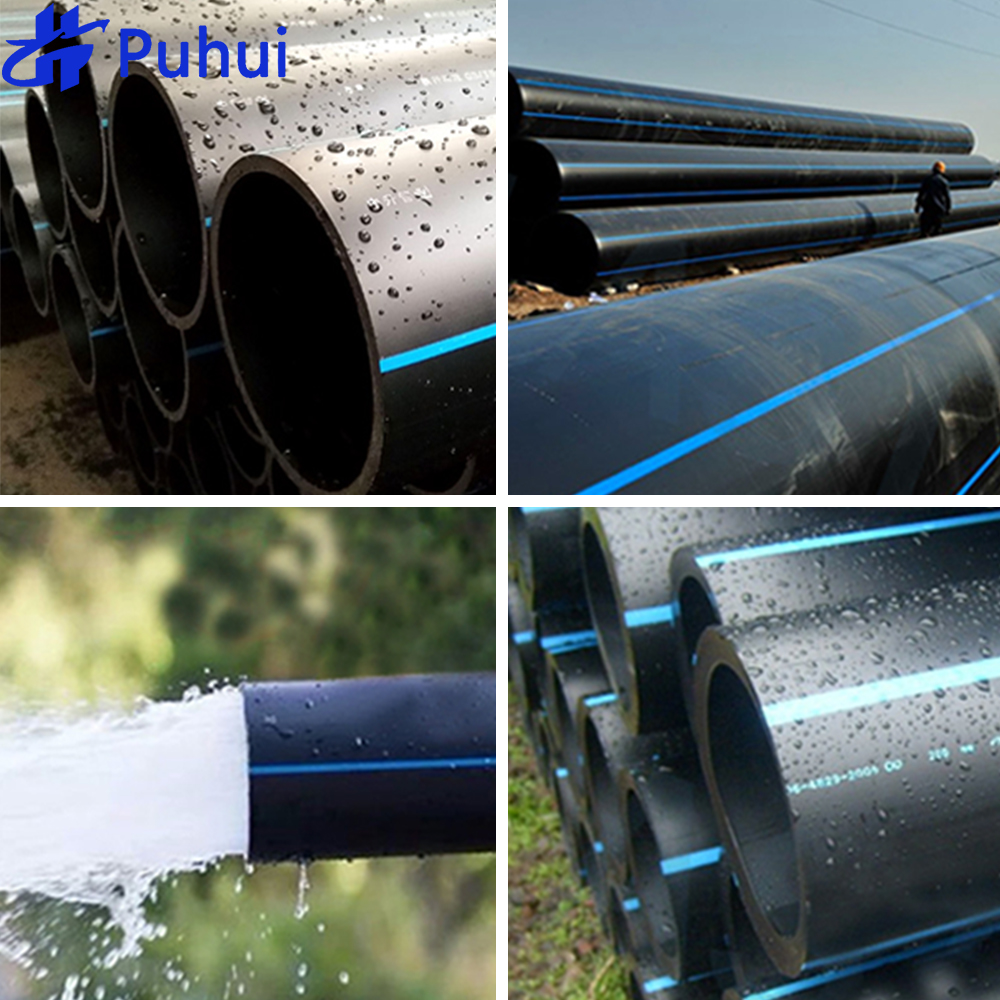

Why are HDPE pipes used?

Why are HDPE pipes used?

HDPE is commonly used in directional boring, plowing, river crossings, pipe bursting and sliplining. … HDPE performs exceptionally well in mining, dredging and similar applications, outwearing many more costly piping materials, and offers excellent corrosion resistance to corrosive acids, bases and salts.

Corrosion and Chemical Resistance – HDPE pipe will not rust, corrode, tuberculate or support biological scale or growth, and has superb chemical resistance compared to traditional pipe materials. HDPE performs exceptionally well in mining, dredging and similar applications, outwearing many more costly piping materials, and offers excellent corrosion resistance to corrosive acids, bases and salts. HDPE is also unaffected by bacteria and fungi, offering resistance to many organic substances.

Superior Flow Characteristics – Because high-density polyethylene pipe is smoother than steel, cast iron, ductile iron, or concrete, a smaller diameter HDPE pipe can produce an equivalent volumetric flow rate at the same pressure.

It has less drag and a lower tendency for turbulence at high flow rates. HDPE’s superior chemical resistance and non-stick surface characteristics nearly eliminate scaling and pitting, preserving the excellent hydraulic characteristics throughout the pipe system’s service life.

It is sometimes called “alkathene” or “polythene” when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber.

Common Uses of hdpe pipe

High-density polyethylene or HDPE is a commonly used petroleum thermoplastic and the most used of the three polyethylenes for a wide range of applications. If you look at this plastic under a microscope, you would see that it has a linear structure with few branches lending to its optimal strength/density ratio. As a result of its molecular makeup, this polymer shines brightest in applications where moisture resistance and cost-effe

ctiveness are needed.

HDPE was created in the 1930s and used in high-frequency radar cables during World War II. It was introduced to the market commercially soon after. While its higher density versions yield a more rigid result, HDPE can vary in flexibility. Low-density grades of the thermoplastic are less stiff and the high-density grades have equally high crystallinity.

The Advantages and Disadvantages of HDPE pipe

Even with its popularity, there are some advantages and disadvantages you should consider before using HDPE for your application:

Advantages

- Cost-effective

- Can withstand temperatures from -148 to 176 degrees Fahrenheit

- Non-leaching

- UV-resistant

- Dishwasher safe

- Resistant to most chemical solvents

- Stiff material

Why so popular? Here’s why:

1.It’s lightweight yet super-strong. That’s why an HDPE milk jug that weighs 2 ounces can carry a gallon of milk. And why many carmakers use HDPE fuel tanks—lighter weight car parts can help increase fuel efficiency.

2.It’s impact resistant. Drop the toy truck down the stairs and it bounces.

3.It’s long lasting and weather resistant, so that plastic lumber deck in the backyard can entertain generations of families.

4.It resists mold, mildew, rotting, and insects, so it’s great for underground pipes used to deliver water.

5.And it’s easily molded into nearly any shape, providing one of the primary benefits of most plastics: malleability.

HDPE PIPE