12

Jan

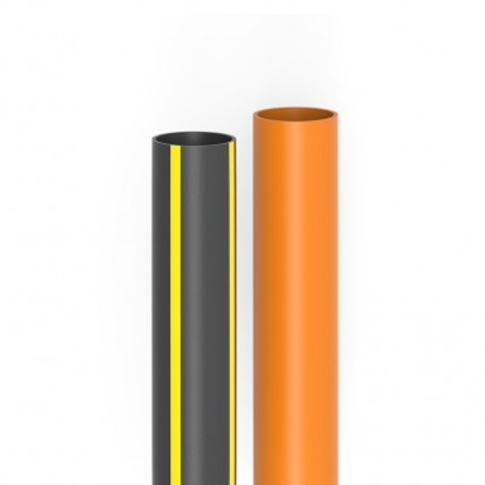

The Superiority of HDPE Gas Pipes in Modern Applications

In the ever-evolving world of gas distribution and infrastructure, High-Density Polyethylene (HDPE) gas pipes have emerged as a front-runner, offering unparalleled advantages over traditional piping materials. This article delves into the myriad benefits of HDPE pipes, particularly focusing on yellow HDPE pipes, PE natural gas pipes, and their role in revolutionizing gas distribution networks.

HDPE pipes, known for their robustness and durability, have become the material of choice in the gas industry. The use of yellow HDPE pipe is particularly notable due to its high visibility, which aids in easy identification and safety compliance in gas distribution. These pipes are not only tough against physical damages but also exhibit exceptional resistance to chemicals and environmental factors, ensuring a long service life with minimal maintenance.

One of the standout features of HDPE pipes is their flexibility, which significantly simplifies installation processes. This flexibility, combined with their lightweight nature, allows for cost-effective transportation and handling, making HDPE an economically viable option for gas infrastructure projects. The ease of joining HDPE pipes through techniques such as butt fusion and electrofusion welding further adds to their installation efficiency, creating a seamless and leak-proof system crucial for gas distribution.

The corrosion-resistant quality of HDPE pipes is another key factor in their growing popularity. Unlike traditional metal pipes, HDPE does not corrode, which means there is no risk of pipe degradation leading to leaks or gas contamination. This inherent resistance to corrosion also means a significant reduction in maintenance costs and efforts, making HDPE pipes a sustainable and long-term solution for gas distribution.

Safety is a paramount concern in gas distribution, and HDPE pipes excel in this regard. The PE natural gas pipes, a variant of HDPE pipes, are designed to withstand high pressure and adverse environmental conditions, ensuring a safe and reliable conduit for natural gas. Their leak-proof nature and resistance to crack propagation make them a safer alternative to conventional piping materials, thereby enhancing the overall safety of the gas distribution network.

In the context of environmental sustainability, HDPE pipes offer a greener alternative. Being a thermoplastic, HDPE can be recycled, reducing the environmental impact of gas distribution projects. Additionally, the lower weight of HDPE pipes translates to reduced carbon emissions during transportation.

From a commercial perspective, incorporating HDPE pipes into gas distribution systems can be a significant selling point. For contractors and suppliers, the numerous benefits of HDPE pipes – from installation ease to long-term durability – can be highlighted to attract clients who are looking for efficient, reliable, and cost-effective solutions for their gas infrastructure needs.

In conclusion, the use of HDPE pipes, particularly yellow HDPE pipes and PE natural gas pipes, marks a significant advancement in the field of gas distribution. Their durability, flexibility, safety features, and environmental friendliness not only meet but exceed the demands of modern gas distribution systems. As the industry continues to evolve, HDPE pipes stand out as the optimal choice for efficient, safe, and sustainable gas infrastructure development. This makes them an invaluable asset for businesses and contractors looking to enhance their service offerings in the gas sector.