28

Sep

7 Common Mistakes To Avoid During HDPE Gas Pipe Installation

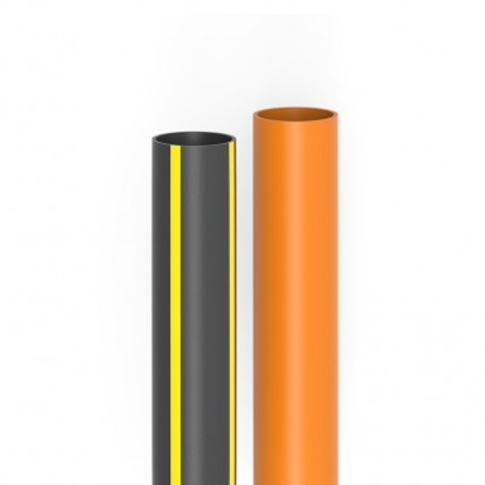

During HDPE gas pipe installation, it is important to avoid certain common mistakes to ensure a successful and durable installation.

7 Common Mistakes To Avoid During HDPE Gas Pipe Installation

1. Insufficient Pipe Bedding

Improper or inadequate pipe bedding can lead to uneven load distribution and stress on the pipe. This can result in deformation, sagging, or even pipe failure. Ensure that the pipe is properly bedded and supported with the appropriate materials, such as sand or granular bedding material, to distribute the load evenly.

2. Inadequate Trench Preparation

Failing to properly prepare the trench can cause issues during installation. The trench should be wide enough to allow for proper jointing, pipe placement, and compaction of backfill material. It should be free from sharp objects, rocks, or debris that could damage the pipe.

3. Improper Fusion Jointing

HDPE gas pipes are typically joined using heat fusion techniques, such as butt fusion or electrofusion. It is crucial to follow the manufacturer’s guidelines and ensure that the fusion jointing is done correctly. Inadequate fusion can result in leaky joints or weak points in the pipeline.

4. Inaccurate Pipe Alignment

Proper pipe alignment is essential for a reliable gas distribution system. Misaligned pipes can cause stress, strain, and increased friction, leading to reduced flow capacity and potential leaks. Ensure that the pipes are aligned properly during installation.

5. Inadequate Backfill Compaction

After the pipes are installed, it is important to properly compact the backfill material around the pipe. Inadequate compaction can lead to settlement and shifting of the pipe, which may cause stress and potential damage.

6. Insufficient Protection from External Factors

HDPE gas pipes should be protected from external factors that can cause damage or degradation. This includes exposure to excessive sunlight, chemicals, or mechanical impacts. Consider using UV-resistant coatings, proper insulation, or protective casings as necessary.

7. Lack of Quality Control and Testing

Insufficient quality control and testing during the installation process can lead to problems down the line. Regular inspections and pressure testing should be conducted to ensure the integrity of the gas pipeline system.

By avoiding these common mistakes, you can help ensure a safe, reliable, and long-lasting HDPE gas pipe installation. If you have any more questions or need further assistance, feel free to contact us!